What tickles your fancy?

(Or just scroll down to keep the adventure going)

A bit about us.

Growing up, we’d spend all our time in the forest, collecting wood to make bows, swords and dens. And that love of making never really left us. But as we got older, it naturally took more of a back seat as we became busier with our day to day lives. But, in 2018 we thought that it would be nice to get back to making stuff again, mainly as an excuse to hangout more. And we figured as we were making stuff, why not film it? If nothing else, our mum would enjoy watching them.

Some years later, and while our mum is still our most loyal fan, we’ve managed to grow from filming (somewhat cringey) videos on our phones in Matt’s garage into something that is not only a full time job with our own premises, but is something that we’re just ridiculously passionate about. While we started the channel looking at DIY across all materials, within a couple of years, we’d shifted to purely focus on sustainable DIY, looking at recycled plastics in particular.

Fast forward and we now have a small, but awesome team behind us and are running a business that we are just stupidly proud of. We’re still very much in the early days, but we’re producing content that is being viewed by millions, seeing people adopt our techniques and shift their perceptions on plastic waste. We’re working with some truly future-focused companies in a number of different ways, be it sponsoring our videos or designing and manufacturing ranges of recycled plastic products for them. And we have our own product line that is developing and growing by the day, so that we can give more and more people the option to ditch single-use plastics and move towards a truly circular economy.

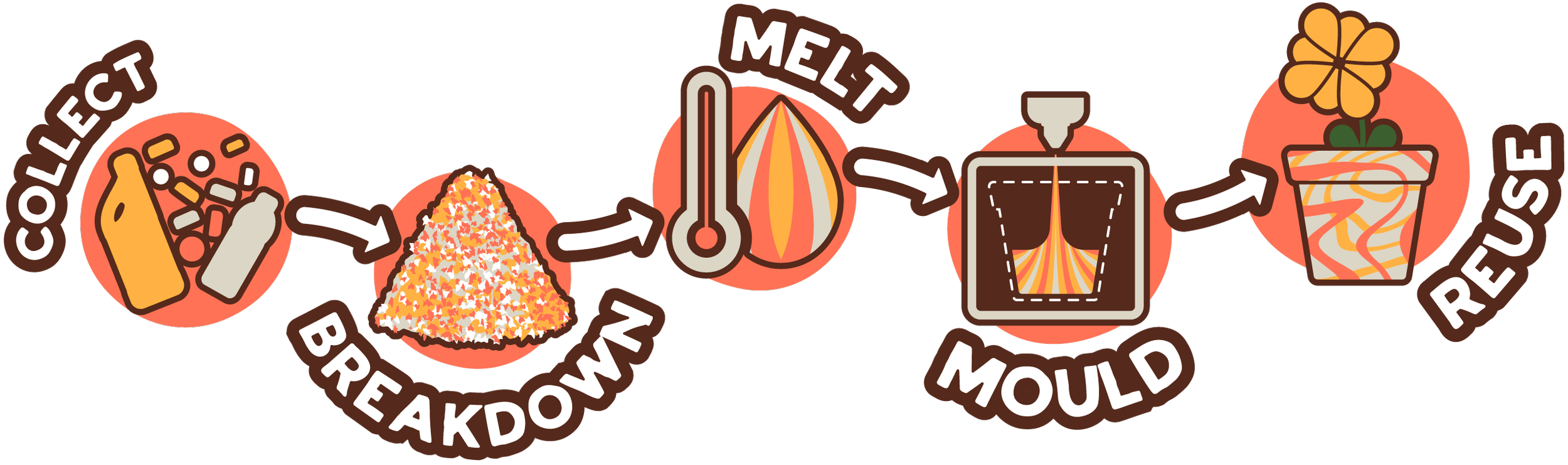

How we give trash a second chance.

All of our products are made from 100% recycled plastic. All the materials that we use are collected by our wonderful friends, family, the local community, businesses and schools. We meticulously clean every piece of plastic that comes to us before hand-sorting it by type and colour. This is by far the longest part of the process, and while it’s by no means the funnest, it is absolutely critical to ensure it is both safe to recycle as well as let the product be recycled again and again in the future. Then comes the fun part of shredding it all down and turning this material into brand new products. And the lovely thing about working with recycled plastic, is that 100% of the waste that is produced can be collected and reused - circular economy, baby.

Back in 1950, 2.5 billion people produced 1.5 million tonnes of plastic.

Fast-forward to 2016, where 7 billion of us pumped out a whopping 320 million tonnes!

- sas.org.uk (2020)

We’ve got a lot to do!

So as you’d expect, melting the plastic requires a heat source. For our DIY method that we show in a lot of our videos, our favourite is a flat-plate sandwich toaster. Once the plastic is melted, we transfer it to a mould and then apply pressure using clamps or a press. This method is perfect for home-recycling, however isn’t a super viable option to scale up into a business. But fortunately there’s some wonderful machinery out there which helps us do exactly that.

So, we purchased a number of machines from our friends at PlasticPreneur, including plastic shredders, extrusion and injection moulding machines. These mean that we can drastically reduce the time it takes to make each product and therefore make it feasible to sell at scale. Dreamy!

Our Mission.

So why do we do it? Well our all-time goal is to help individuals and communities become actively engaged in creating a more sustainable, conscious world, driven by a truly circular economy. As for us, this gives us true meaning in getting up, putting on our grubby old boots and heading to the workshop every day. Because, well, what better reason could there be?!

To do this, we need to educate, encourage and entertain as many people as we possibly can so that we can all change our relationship with consumption and plastic waste. But we’re not here to guilt-trip people into changing their ways, that’s not really our style. While it’s an extremely serious issue, that doesn’t mean we’re going to be super serious - where’s the fun in that? We’re all about bringing energy and an upbeat attitude to empower communities. Bringing positivity to create positive change. Wholesome, right?

The Recycle Squad.

Here’s the team in all their glory. Four brave heroes, on the front line. Each armed with cameras, injection moulders and plenty of snacks in the fight against single use plastic (boo, single-use sucks).

Matt

-

One of said brothers, Matt is the older and arguably the slightly more sensible of the two. Prior to Brothers Make, his degree was in architecture before going on to teach Product Design. So fortunately he brings a lot of much needed practical knowledge to the business, usually being the one having to work out the tricky technicalities that present themselves on a daily basis. Fortunately, he loves that stuff so it works out well for everyone.

Loves: His kids, Formula E, poker, spending too much on everyday carry items and Lord of the Rings.

Hates: Mornings.

JONNY

-

The other of said brothers, Jonny the younger and typically slightly more annoying brother. While enjoying DIY as a hobby, prior to Brothers Make, his degree was in Business Management and he had career in marketing. Fortunately this has worked out nicely, as paired with Matt’s practical abilities, these seem to make a pretty good combination for running a business, particularly one focused on content creation!

Loves: Hiking, cold water, surfing, anything to do with his campervan and of course, Lord of the Rings.

Hates: The song ‘Sweet Caroline’.

HANNAH

-

Being a former student of Matt’s, fortunately Hannah is highly experienced in putting up with his morning grumpiness and knows how to get her way by providing sweet treats. She’s an extremely meticulous member of the team, having a great eye for making sure our products are perfect before being sent out. Outside of Brothers Make she also designs her own range of gifts and products, each with a unique, anatomically-inspired design.

Loves: Baking, art, highland cows, Chicago Town pizzas and unfortunately, Mamma Mia.

Hates: Matt’s dad jokes.

GEORGE

-

Being renowned in equal parts for his awesome design ability and his diabolical impression skills, George is the creative eye of the team, being sure that everything is looking as rad as possible before it leaves the workshop. He and Jonny go way back, having spent much of their teenage years getting drunk at the park or down the beach. Outside of Brothers Make, he is a freelance designer, helping others look as cool as he does.

Loves: Apples, desk accessories, pronouncing things wrong, Gorillaz and this kid.

Hates: How much he looks like Craig David.

Take a Peek in our Diary.

1 Nov - 24 Dec 2024

Handmade for Christmas

Workhouse Chapel, Sturminster Newton